TM 5-4220-211-12&P

Section I

GENERAL INFORMATION

A-2.

DIESEL 4 CYCLE OPERATION

Farymann engines, like their larger brothers in automotive, agricultural and industrial equipment, are 4 cycle diesels.

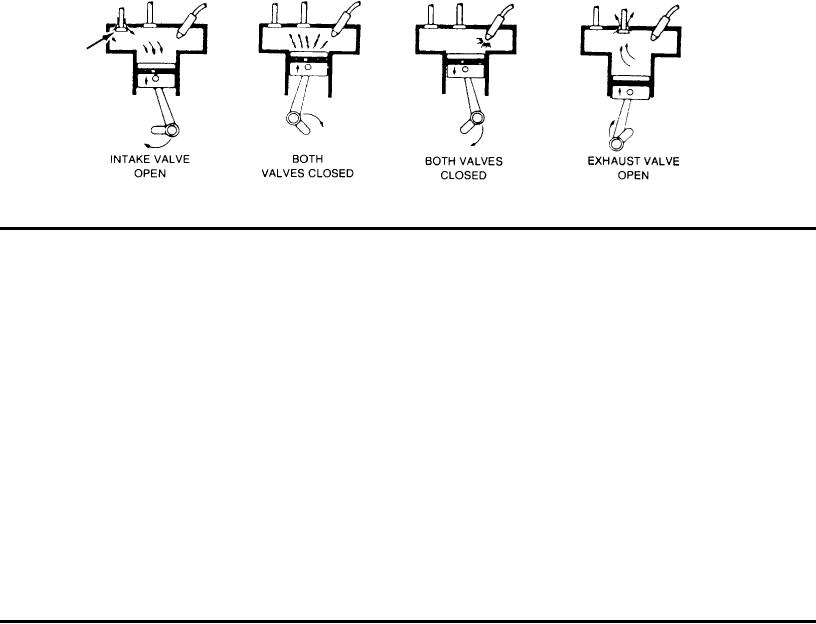

These four cycles, or strokes, are intake, compression, power and exhaust.

a. The intake stroke begins with the piston moving down, creating a vacuum which draws air through the open

intake valve into the space above the piston.

b. With both valves closed, the piston rises, compressing the air into the very small space remaining between

the piston top and cylinder head and causing a tremendous rise in air temperature.

c. The fuel injector now sprays a fine mist of diesel fuel directly into this space, where the high temperature of

the compressed air causes it to ignite and drive the piston downward.

d. After the piston has reached the limit of its downward travel, momentum causes it to begin moving upward

once again. At this point, the exhaust valve opens and the piston forces out all of the burnt gases, completing one cycle.

Table A-1. PREVENTIVE MAINTENANCE

Daily:

Check engine oil level.

Oilbath aircleaner - check oil level, if atmosphere is dusty, clean daily.

Drytype aircleaner - under (lusty conditions check daily, renew paper cartridge if

necessary

After 20 hours:

Change oil and check valve clearance on all new or rebuilt engines. Check all nuts and

bolts for tightness (for tightening torques see chart page 3).

Every 100 hours:

Change oil

Check V-belt tension (generator, waterpumps etc.)

Oilbath aircleaner -- clean thoroughly (earlier when necessary)

Drytype airfilter - renew paper cartridge if necessary

Check valve clearance (engine cold).

Check all fuel lines for leakages

Under dusty conditions: clean cooling air intake, blower in flywheel and cooling fins on

cylinder and cylinder head

Every 300 hours:

Change oil

Renew oil filter (2-cylinder engines only)

Clean oil strainer

Flush crankcase (if sludge is present)

Check decompression device

Every 500 hours:

Check and clean crankcase breather

Clean fuel tank

Fuel filter - check and renew cartridge if necessary

A-2