TM 5-4220-211-12&P

(3)

Connect separator discharge line (29, Fig. D-11) at separator and at third stage valve head (10, Fig. D-

7). Tighten line nuts securely.

t.

Install compressor into frame. (Ref. para 4-12.)

u.

Fill compressor with oil. (Ref. para 4-4.)

v. Start compressor. (Ref. para 3-5.) Bleed air from oil pump. Ref. para 4-25). Check all fittings for leaks.

Repair as required.

4-26.

ENGINE. Reassembly of the engine is covered in Appendix A.

4-27.

PURIFIER CHAMBER. The purifier chamber may be reassembled as follows:

a. Install O-rings (4 and 5, Fig. D-13) into grooves in top and bottom plugs (1 and 3, Fig. D-13). Install cartridge

O-ring (6, Fig. D-13) into groove in bottom plug (3, Fig. D-13).

NOTE

Back-up ring is installed at the end of the O-ring groove nearest plug threads and with the

flat face against the face of the O-ring groove.

b.

Apply a thin film of silicone grease to the O-rings, backup rings and plug threads.

c.

Install purifier cartridge. Ref. para 4-4.

d. Slip chamber (2, Fig. D-13) down over cartridge (7, Fig. D-13), screw chamber down on bottom plug (3, Fig.

D-13) until chamber comes down flush with bottom plug. Do not overtighten.

e.

Install top plug. Ref. para. 44.

4-28.

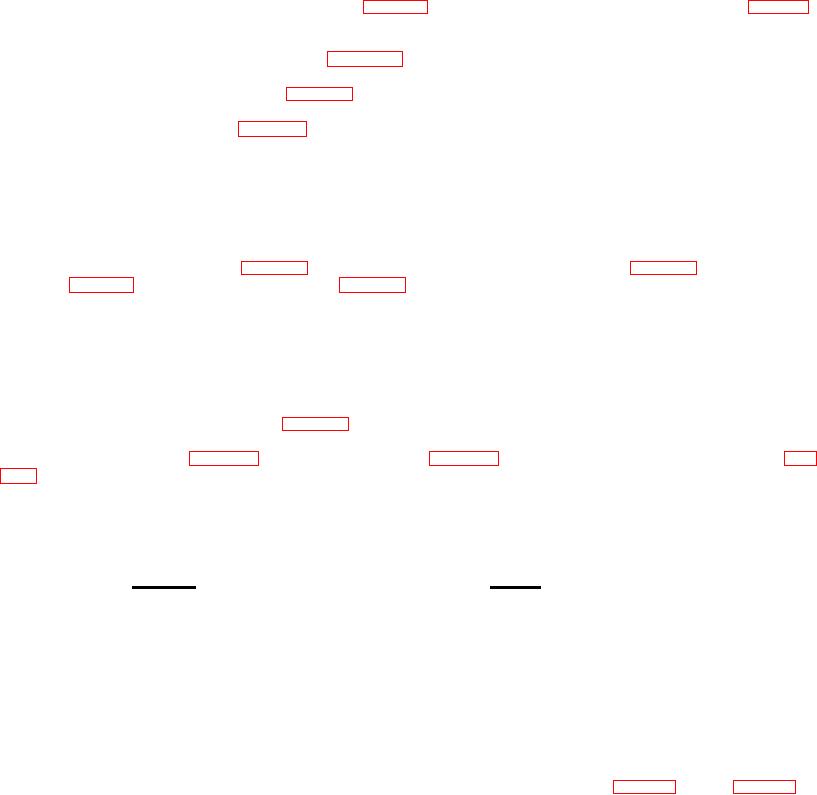

TORQUE LIMITS. Unless otherwise specified, the following torque limits shall apply.

Bolt Size

6 mm

7 ft-lbf (10 NM)

8 mm

18 ft-lbf (25 NM)

10 mm

32 ft-lbf (44 NM)

1/4"-20

6-9 ft-lbf (8-13 NM)

1/4"-28

6-9 ft-lbf (8-13 NM)

5/16"-18

12-15 ft-lbf (17-21 NM)

5/16"-24

15-18 ft-lbf (21-25 NM)

3/8"-16

23-28 ft-lbf (32-39 NM)

3/8"-24

30-35 ft-lbf (42-49 NM)

4-29. SPECIAL TOOLS. A valve tool for removing second and third stage inlet valves (4, Fig. D-6) and (1, Fig. D-7) is

provided with this compressor unit. Valve tool part number is 4555.

4-25/(4-26 blank)