TM 5-4220-211-12&P

d.

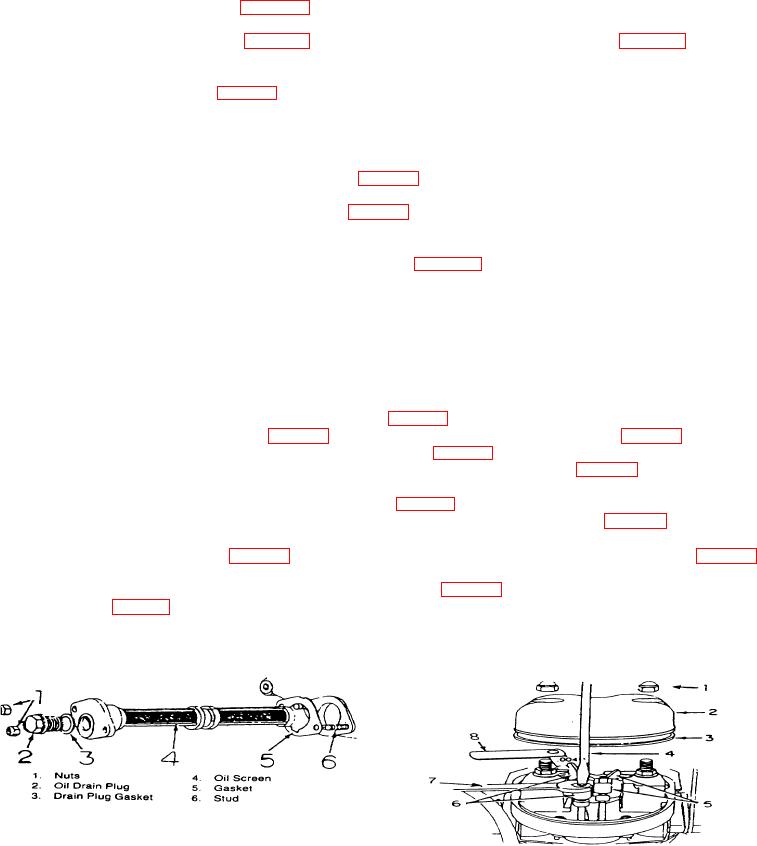

Clean Engine Crankcase Oil Screen. Clean the engine crankcase oil screen as follows:

(1)

Drain engine oil. Ref. Para 4-5.

(2) Remove two nuts (1, Fig. 4-5).

Remove oil screen and gasket (4 and 5, Fig. 4-5) from engine

crankcase.

(3)

Clean oil screen (4, Fig. 4-5) with fresh diesel fuel.

(4) Flush engine crankcase with fresh diesel fuel.

Then flush engine crankcase with fresh engine

lubricating oil.

(5)

Inspect oil screen and gasket (4 and 5, Fig. 4-5) for damage. Replace damaged parts.

(6)

Install oil screen and gasket (4 and 5, Fig. 4-5) into engine crankcase. Secure with two nuts (1, Fig. 4-

5).

(7)

Refill engine crankcase with lubricating oil. Ref. Para 4-5.

NOTE

Clean engine oil screen after the first 20 hours of operation and every 250 hours/12 mos. thereafter.

e.

Adjust Engine Valves. Adjust the engine valves as follows:

(1) Engine must be at room temperature. Allow the engine to cool at least 12 hours after operation before

adjusting valves.

(2) Make sure automatic compression release (8, Fig. 1-3) is in "RUN" position.

(3) Remove two acorn nuts (1, Fig. 4-6). Remove valve cover and gasket (2 and 3, Fig. 4-6).

(4) Rotate engine until the exhaust valve rocker arm (6, Fig. 4-6) is fully open.

(5) Check clearance between intake valve stem and intake rocker arm (5, Fig. 4-6). Loosen locknut and

adjust valve to rocker arm clearance as required to obtain .004" (.1mm) clearance.

(6) Rotate engine until intake valve rocker arm (5, Fig. 4-6) is fully open.

(7) Check clearance between exhaust valve stem and exhaust rocker arm (6, Fig. 4-6). Loosen locknut

and adjust as required to obtain .004" (.1mm) clearance.

(8) Clean valve cover (2, Fig. 4-6) in mineral spirits. Inspect valve cover and gasket (2 and 3, Fig. 4-6) for

damage. Replace damaged parts.

Assemble valve cover and valve cover gasket (2 and 3, Fig. 4-6) to cylinder head. Secure with two acorn

nuts (1, Fig. 4-6).

NOTE

Adjust engine valves after the first 20 hours of operation and every 250 hours/12 mos. thereafter.

Figure 4-5. Diesel Engine Crankcase Oil Screen

Figure 4-6. Diesel Engine Valve Adjustment

Change 3 4-9