TM 5-4220-211-12&P

(2)

Clean the aftercooler coil (6, Fig. D-8) using a soft brush or low pressure air.

(3)

Inspect all cooler coils for damage. Replace damaged coils.

j.

Compressor Assembly Inspection. Inspect the complete compressor assembly (Fig. D-2) for loose,

damaged or missing items. Repair or replace damaged or missing items.

k.

First Stage Valve Replacement. Replace first stage valve assembly (Fig. D-5) as follows:

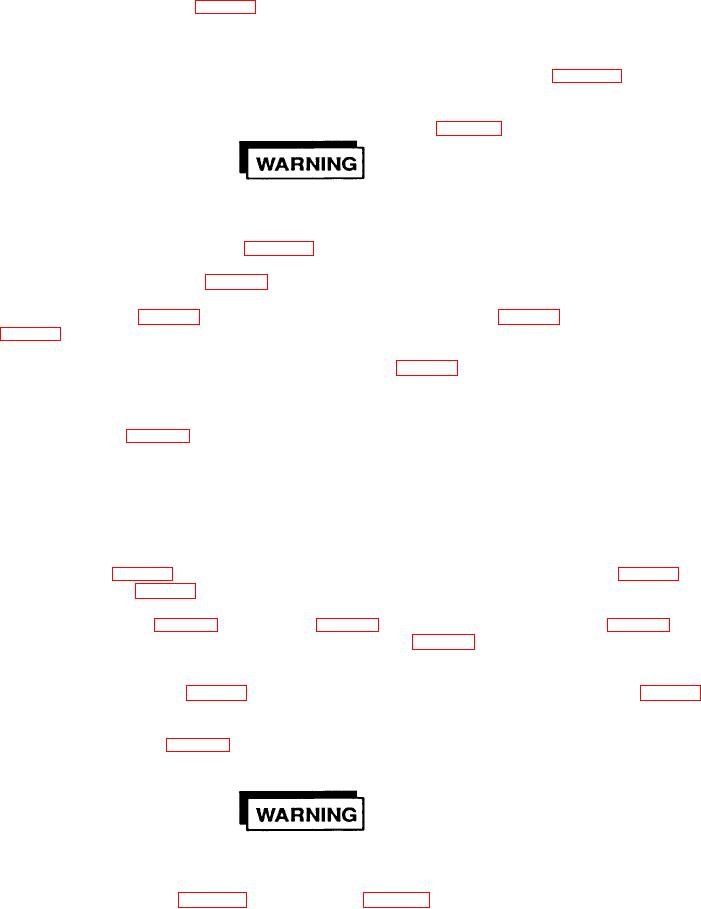

Compressor piping may cause high pressure. Never attempt to service or repair any

portion of the compressor until all pressure has been released to the atmosphere.

(1)

Remove inlet air filter assembly (1, Fig. D-10).

(2)

Disconnect discharge line (7, Fig. D-5).

(3) Remove 3 bolts (9, Fig. D-5). Remove hex nut and washer (11 and 10, Fig. D-5). Remove valve head

(1, Fig. D-5).

(4)

Remove first stage inlet and discharge valve assembly (5, Fig. D-5).

(5)

Clean valve in mineral spirits. Metallic components may also be cleaned in lacquer thinner.

(6) Inspect valve (5, Fig. D-5) for wear and damage. The seating surface of each plate should be clean,

bright and free of excessive wear. Damaged or worn valve must be replaced.

NOTE

Always replace complete valve assembly.

(7)

Check for free movemen t of valve reeds.

(8) Place gasket (6, Fig. D-5) on first stage cylinder, place first stage inlet and outlet valve (5, Fig. D-5) on

gasket, place gasket (4, Fig. D-5) on top of valve assembly.

(9) Place valve head (12, Fig. D-5) over stud (8, Fig. D-5) on cylinder. Install washer (10, Fig. D-5) and

screw Hex Nut down stud. Screw in three socket head bolts (9, Fig. D-5). Tighten Hex Nut and bolts to a

torque of 18ft-lbf. (25 NM).

(10) Connect discharge line (7, Fig. D-5). Tighten line nuts securely. Connect oil breather hose (13, Fig. D-

5) to valve head.

(11) Install inlet air filter (1, Fig. D-10).

l.

Second Stage Valve Replacement. Replace second stage valve assembly as follows:

Compressor piping may contain high pressure. Never attempt to service or repair any

portion of the compressor until all pressure has been released to the atmosphere.

(1)

Remove safety valve (23, Fig. D-11) and gasket (24, Fig. D-11).

NOTE

Do not readjust safety valve.

4-5