TM 5-4220-211-12&P

c.

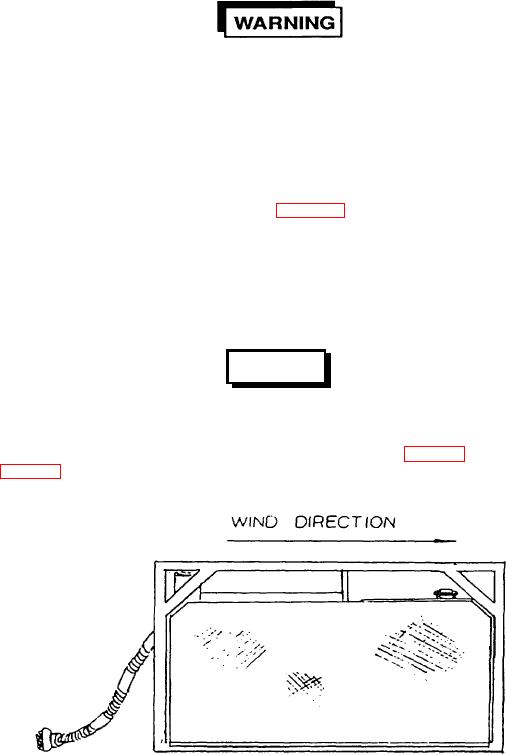

Reposition unit accordingly as the wind changes direction.

d.

Be certain that no exhaust from running vehicles are in the vicinity of the unit.

e. Check ambient air for carbon monoxide and carbon dioxide contamination with the Detector Set. Compare

the results with Table 1-1. Change the operation site if these levels are excessive.

The location of the compressor intake with respect to possible sources

of contamination is fully as important as any single factor in assuring

satisfactory air quality. The compressor unit should not be operated

near exhausts of internal combustion engines, sewer manholes,

sandblasting, painting, electric arcs, or sources of smoke.

f.

The compressor unit, since it is diesel powered, must be located outdoors, never indoors.

g.

Place compressor unit on level surface. Refer to Table 1-2 for maximum permissible inclination.

Section III

PREPARATION FOR STORAGE

2-4.

SHORT TERM STORAGE. Short term storage of the compressor unit, storage of about 6 months or less, may be

accomplished by performing the following steps.

WARNING

All work performed on the compressor unit must be accomplished only

while the unit is depressurized.

a. Run the compressor unit at operating pressure (open drain valve 13, Fig. D-2) to maintain 3000 PSI on final

pressure gauge (19, Fig. D-2) and temperature for approximately 10 minutes. All other valves should be closed.

Figure 2-1. Orientation of Compressor Unit with Respect to Wind and Air Intake Hose

2-3