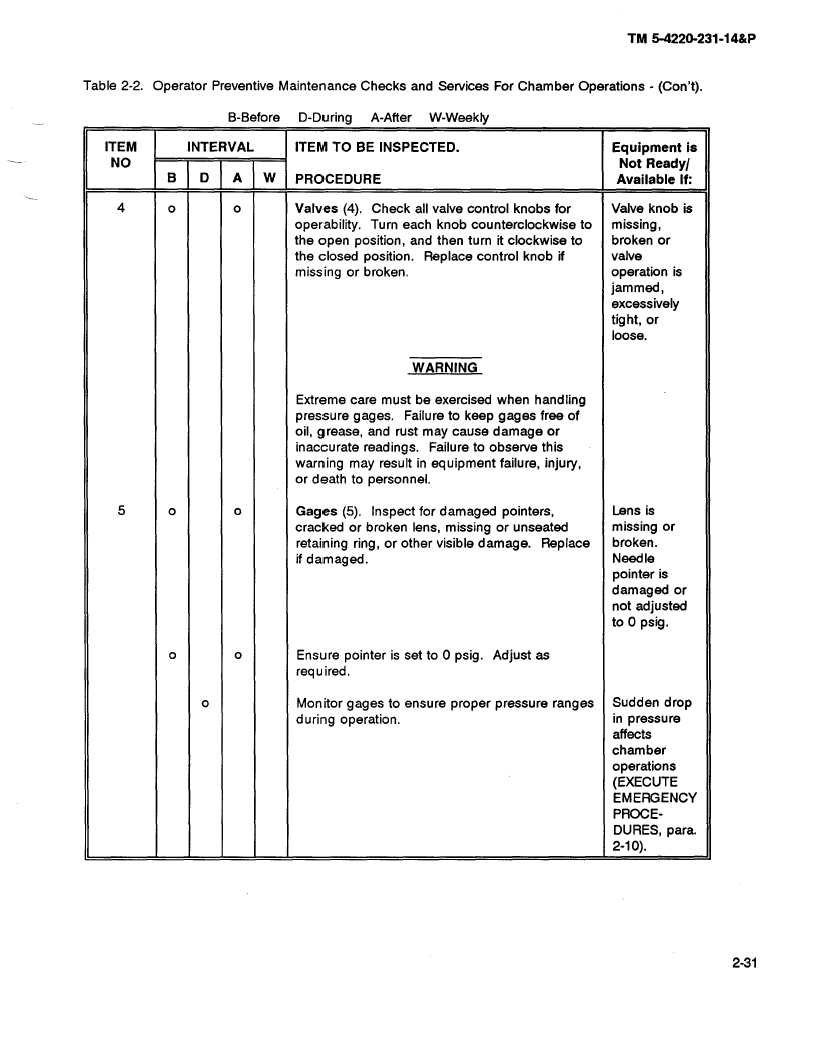

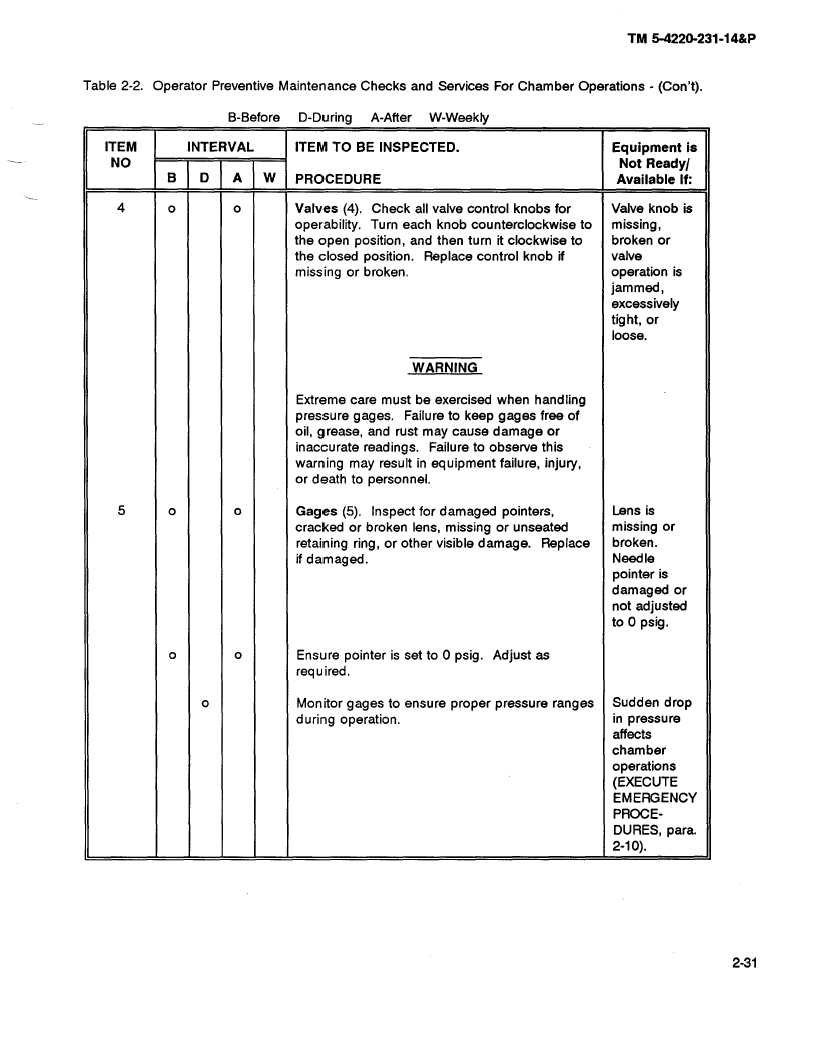

TM 5-4220-231-14&P

Table 2-2. Operator Preventive Maintenance

Checks and Services For Chamber Operations

- (Con't).

B-Before

D-During

A-After

W-Weekly

ITEM

INTERVAL

ITEM TO BE INSPECTED.

Equipment

Is

NO

Not Ready/

B

D

A

W

PROCEDURE

Available

If:

4

0

0

Valves

(4).

Check

all valve control

knobs for

Valve knob is

operability.

Turn each

knob counterclockwise

to

missing,

the open

position,

and then turn it clockwise

to

broken

or

the closed

position.

Replace

control

knob if

valve

missing

or broken.

operation

is

jammed,

excessively

tight, or

loose.

WARNING

Extreme

care must

be exercised

when

handling

pressure

gages.

Failure to keep gages

free of

oil, grease,

and rust may cause

damage

or

inaccurate

readings.

Failure to observe

this

warning

may result in equipment

failure,

injury,

or death

to personnel.

5

0

0

Gages

(5).

Inspect

for damaged

pointers,

Lens is

cracked

or broken

lens, missing

or unseated

missing

or

retaining

ring, or other visible damage.

Replace

broken.

if damaged.

Needle

pointer

is

damaged

or

not adjusted

to 0 psig.

0

0

Ensure

pointer

is set to 0 psig.

Adjust as

required

.

0

Monitor

gages

to ensure

proper

pressure

ranges

Sudden

drop

during

operation.

in pressure

affects

chamber

operations

(EXECUTE

EMERGENCY

PROCE-

DURES,

para.

2-10).

2-31