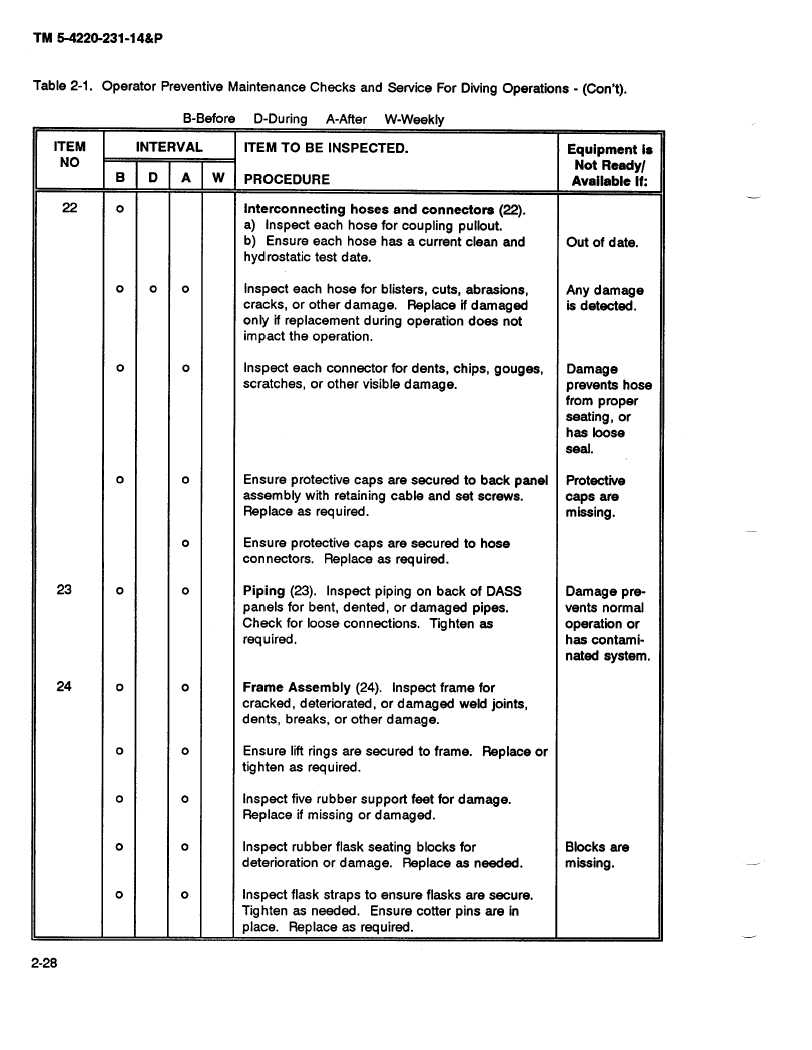

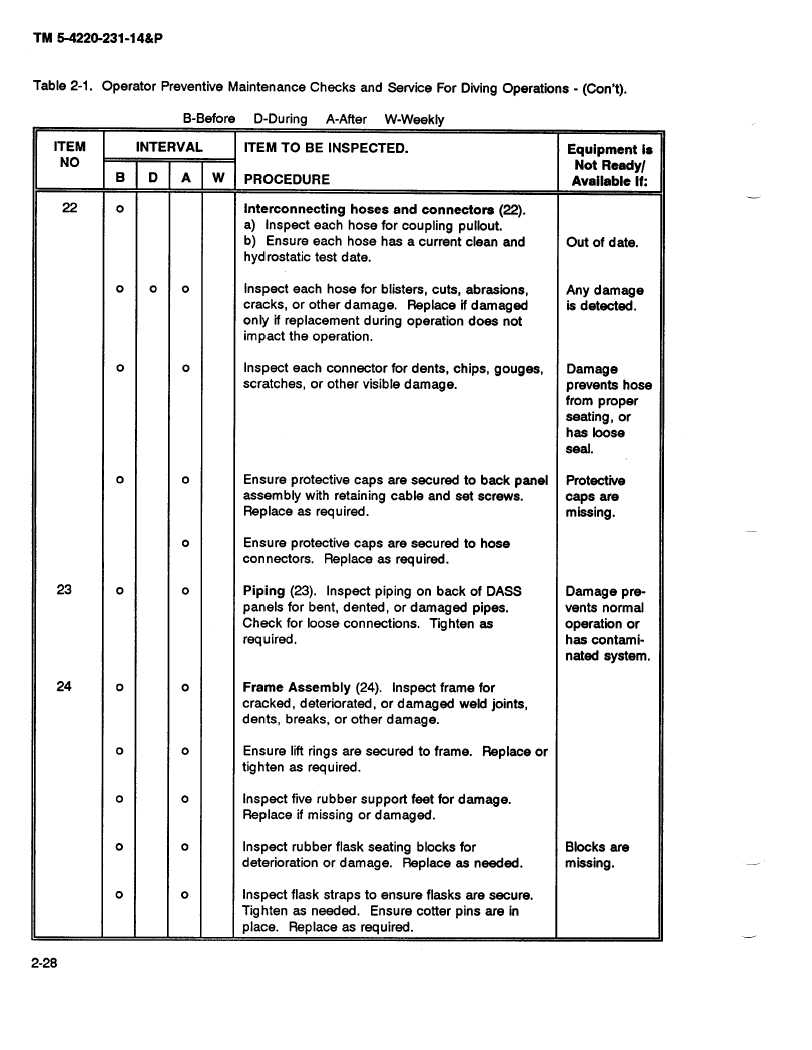

TM 5-4220-231-14&P

Table 2-1. Operator

Preventive

Maintenance

Checks

and Service

For Diving Operations

- (Con't).

B-Before

D-During

A-After

W-Weekly

ITEM

INTERVAL

ITEM TO BE INSPECTED.

Equipment

I

NO

Not Ready/

D A

W

PROCEDURE

Available

If:

22

0

Interconnecting

hoses

and connectors

(22).

a) Inspect

each

hose for coupling

pullout.

b) Ensure

each

hose has a current

clean and

Out of date.

hydrostatic

test date.

0

0

0

Inspect

each

hose for blisters,

cuts, abrasions,

Any damage

cracks,

or other damage.

Replace

if damaged

is detected.

only if replacement

during

operation

does

not

impact

the operation.

0

0

Inspect

each connector

for dents,

chips,

gouges,

Damage

scratches,

or other visible damage.

prevents

hose

from proper

seating,

or

has loose

seal.

0

0

Ensure

protective

caps

are

secured

to back

panel

Protective

assembly

with retaining

cable

and

set

screws.

caps

are

Replace

as required.

missing.

0

Ensure

protective

caps

are

secured

to hose

connectors.

Replace

as required.

23

0

0

Piping

(23).

Inspect

piping

on back

of DASS

Damage

pre-

panels

for bent,

dented,

or damaged

pipes.

vents

normal

Check

for loose

connections.

Tighten

as

operation

or

required.

has

contami-

nated

system.

24

0

0

Frame

Assembly

(24).

Inspect

frame

for

cracked,

deteriorated,

or damaged

weld joints,

dents,

breaks,

or other

damage.

0

0

Ensure

lift rings

are

secured

to frame.

Replace

or

tighten

as required.

0

0

Inspect

five rubber

support

feet for damage.

Replace

if missing

or damaged.

0

0

Inspect

rubber

flask

seating

blocks

for

Blocks

are

deterioration

or damage.

Replace

as needed.

missing.

0

0

Inspect

flask straps

to ensure

flasks

are

secure.

Tighten

as needed.

Ensure

cotter

pins

are

in

place.

Replace

as required.

2-28