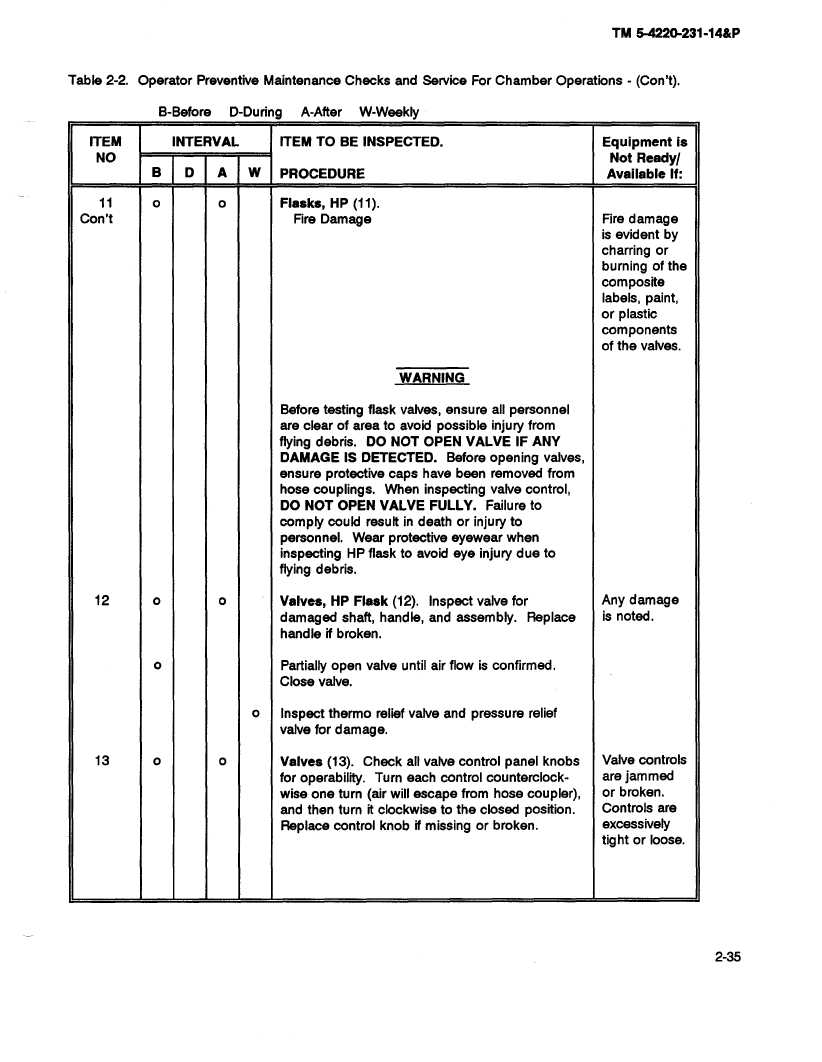

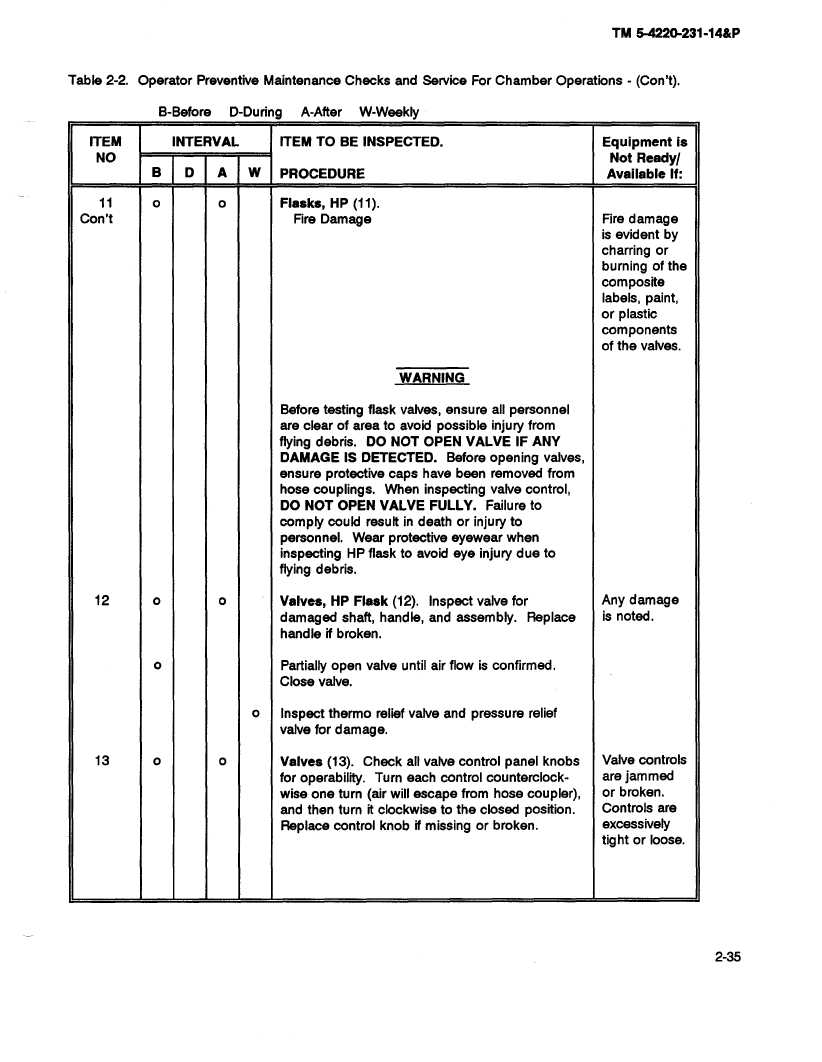

TM 5-4220-231-14&P

Table

2-2.

Operator

Preventive

Maintenance

Checks

and

Service

For Chamber

Operations

- (Con't).

B-Before

D-During

A-After

W-Weekly

ITEM

INTERVAL

ITEM TO BE INSPECTED.

Equipment

is

NO

N

Ready/

B

D

A

W

PROCEDURE

Available

If:

11

0

0

Flasks,

HP (11).

Con't

Fire Damage

Fire damage

is evident

by

charring

or

burning

of the

composite

labels,

paint,

or plastic

components

of the

valves.

WARNING

Before

testing

flask

valves,

ensure

all personnel

are clear

of area

to avoid

possible

injury from

flying debris.

DO NOT OPEN

VALVE

IF ANY

DAMAGE

IS DETECTED.

Before

opening

valves,

ensure

protective

caps

have

been

removed

from

hose

couplings.

When

inspecting

valve control,

DO NOT OPEN VALVE FULLY.

Failure

to

comply

could

result

in death

or injury to

personnel.

Wear

protective

eyewear

when

inspecting

HP flask to avoid

eye

injury due

to

flying

debris.

12

0

0

Valves,

HP Flask

(12).

Inspect

valve for

Any damage

damaged

shaft,

handle,

and

assembly.

Replace

is noted.

handle

if broken.

0

Partially

open

valve

until air flow is confirmed.

Close

valve.

o

Inspect

thermo

relief valve

and

pressure

relief

valve

for damage.

13

0

0

Valves

(13).

Check

all valve control

panel

knobs

Valve controls

for operability.

Turn each

control

counterclock-

are jammed

wise one

turn (air will escape

from

hose

coupler),

or broken.

and

then

turn it clockwise

to the

closed

position.

Controls

are

Replace

control

knob

if missing

or broken.

excessively

tight or loose.

2-35