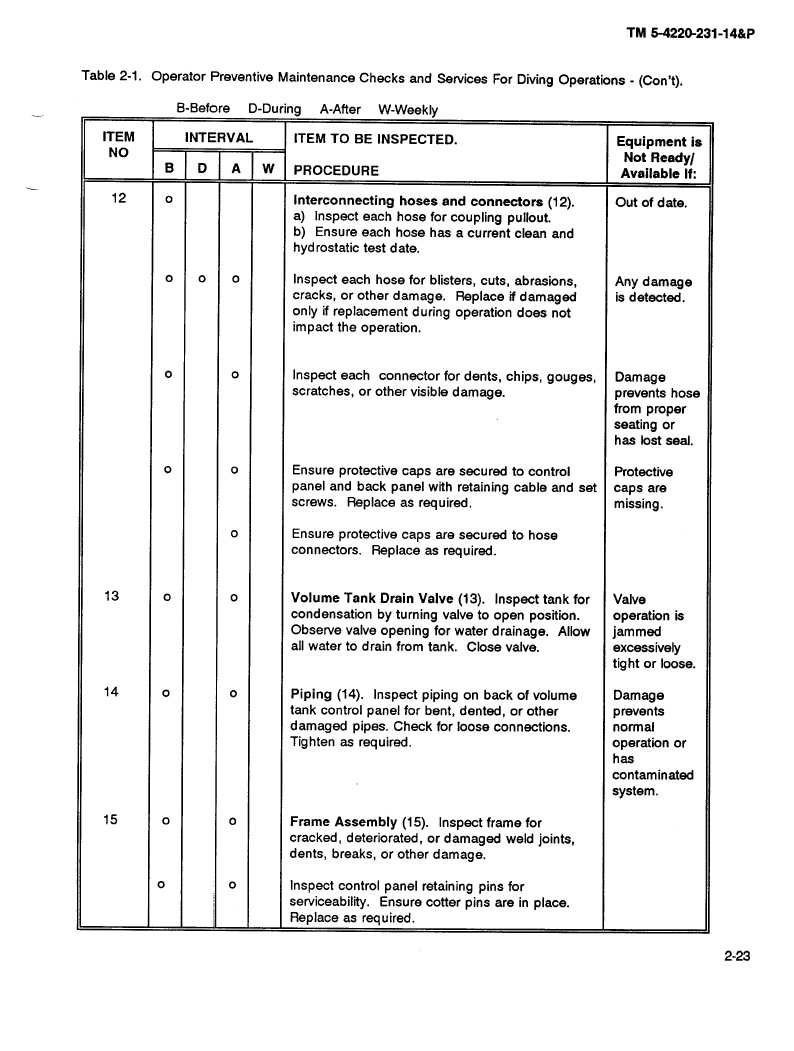

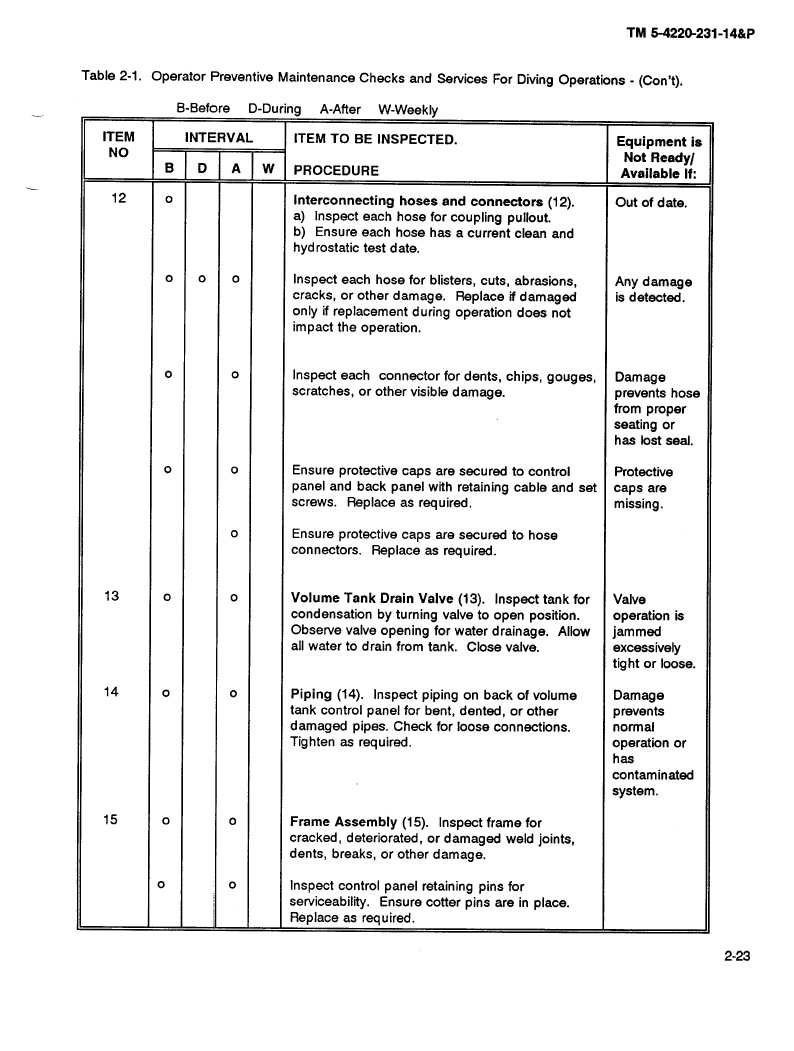

TM 5-4220-231-14&P

Table 2-1.

Operator

Preventive

Maintenance

Checks

and Services

For Diving Operations

- (Con't).

B-Before

D-During

A-After

W-Weekly

ITEM

INTERVAL

ITEM TO BE INSPECTED.

Equipment

is

NO

Not Ready/

ID

A FW

PROCEDURE

Available

If:

12

0

Interconnecting

hoses

and connectors

(12).

Out of date.

a)

Inspect

each

hose

for coupling

pullout.

b)

Ensure

each

hose

has a current

clean

and

hydrostatic

test

date.

0

0

0

Inspect

each

hose

for blisters,

cuts,

abrasions,

Any damage

cracks,

or other

damage.

Replace

if damaged

is detected.

only if replacement

during

operation

does

not

impact

the

operation.

0

0

Inspect

each

connector

for dents,

chips,

gouges,

Damage

scratches,

or other

visible

damage.

prevents

hose

from proper

seating

or

has

lost seal.

0

0

Ensure

protective

caps

are

secured

to control

Protective

panel

and

back

panel

with retaining

cable

and

set

caps

are

screws.

Replace

as required.

missing.

0

Ensure

protective

caps

are secured

to hose

connectors.

Replace

as required.

13

0

0

Volume

Tank

Drain

Valve

(13).

Inspect

tank

for

Valve

condensation

by turning

valve to open

position.

operation

is

Observe

valve

opening

for water

drainage.

Allow

jammed

all water

to drain

from tank.

Close

valve.

excessively

tight or loose.

14

0

0

Piping

(14).

Inspect

piping

on back

of volume

Damage

tank

control

panel

for bent,

dented,

or other

prevents

damaged

pipes.

Check

for loose

connections.

normal

Tighten

as

required.

operation

or

has

contaminated

system.

15

0

0

Frame

Assembly

(15).

Inspect

frame

for

cracked,

deteriorated,

or damaged

weld joints,

dents,

breaks,

or other

damage.

0

0

Inspect

control

panel

retaining

pins for

serviceability.

Ensure

cotter

pins

are

in place.

Replace

as required.

2-23