TM 5-4220-211-12&P

Consequently, the rate of flow of the air in the DRAGER tube which is decisive for the accuracy of measurement, is

determined exclusively by the spring force of the pump and the resistance of the tube filling, which is fixed during

manufacture. To check that testing takes place correctly, see also the section on Opening time in the Tube Operation

Instructions.

When testing, make the number of pump strokes specified in the Operating Instructions for the Tube concerned.

Section IV

B-4. MAINTENANCE OF THE BELLOWS PUMP.

a. Leak Testing. It is wise to check the pump for leaks every time it is used. To do this, seal the pump

with an unopened DRAGER Tube and completely compress the bellows. The pump is sufficiently air-tight if the

bellows has not expanded again completely after 10 minutes, i.e. the limit chain is not taut. It will then deliver the

volume required.

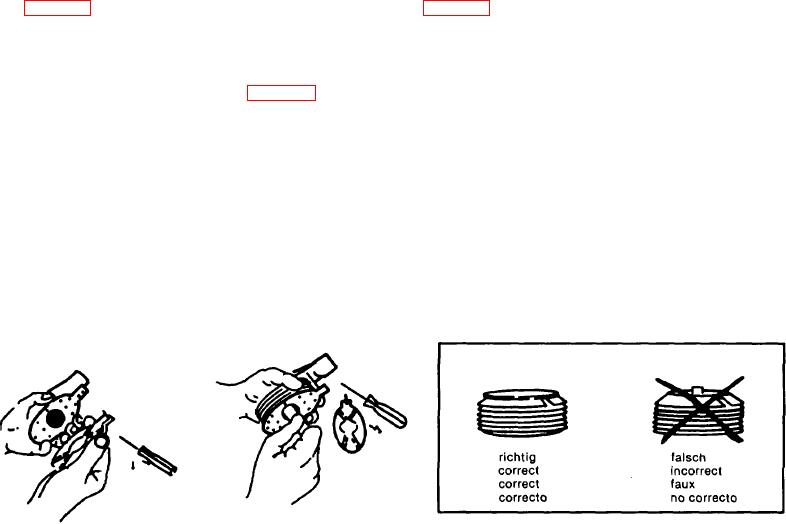

b. Eliminating Leaks. Any leaks can usually be eliminated by cleaning the valve. To do this, remove the front

plate (Fig. B-10) and unscrew the valve using the special spanner (Fig. B-11). Raise the valve disc to prevent it from being

damaged by the spanner. Clean the valve by blowing it through with air or by rinsing it with water. Dry after cleaning.

If the rubber of the valve disc is sticky, brittle, hard or cracked, it must be replaced. Remove the pin from the valve seat

stem and push in the pin of the new valve disc until

the disc lies flat against the valve seat (Fig. B-12). It is best to moisten the pin a little first. When fitting the cover plate,

ensure that the limit chain is not twisted and that the fixing hook lies in the longitudinal direction of the pump, so that it fits

satisfactorily in the slot of the cover plate.

c. Cleaning of the metal screen. After prolonged use of the bellows pump, the wire mesh sieve under the

rubber bung in the pump head may become blocked. The sieve must, therefore, be cleaned from time to time, about

every four weeks when the pump is used frequently. Loosen the two-hole nut with the special spanner and remove the

rubber bung. Take out the sieve and clean it with a brush under running water. When re-inserting the two-hole nut,

tighten it only until the rubber bung is just under stress and the DRAGER Tube can be inserted easily, but tightly.

d. Flushing the Pump with Air. During testing, certain tube types give off vapours which pass into the interior of

the bellows pump (e.g., sulphuric acid mist). To prevent corrosion, flush out the pump with air by making a few strokes

without a detector tube every time it has been used.

Figure B-10.

Figure B-11.

Figure B-12.

Front Plate

Special Spanner

Disc

B-3