TM 5-4220-211-12&P

b.

Any of the baffles or ducts are removed, the flywheel fan is damaged, or cooling fins clogged with debris.

A-15. COOLING SYSTEM MAINTENANCE. No routine cooling system maintenance is necessary. Periodically however,

check to make sure the flywheel fan is in good condition, the finned areas of the cylinder and head are clean and the

intake screens clear of obstructions.

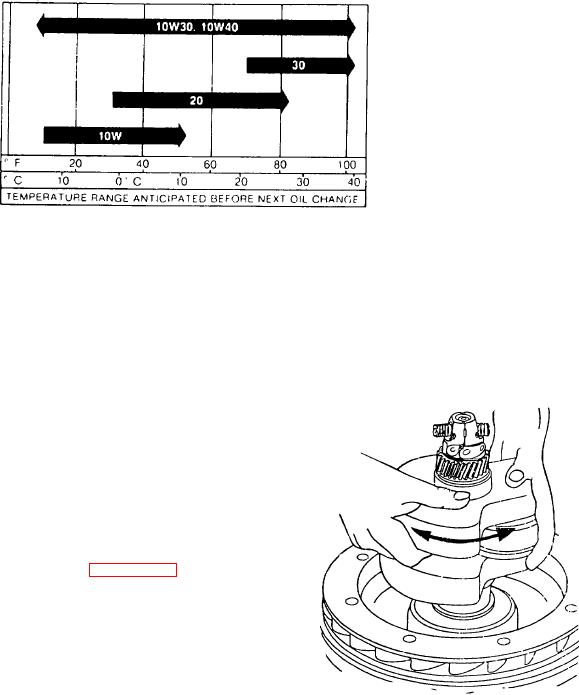

Figure A-75. Lubrication System Maintenance

Section VI

REPAIR GUIDELINES AND SPECIFICATIONS

A-16. REBUILDING GUIDELINES.

a. Crankshaft and Connecting Rod Bearings: Should the crankshaft bearing journals show evidence of wear

or damage, regrinding to .25 or .5 mm undersize may restore bearing surfaces. Roller main bearings must be pulled out

and replaced with new parts. Models 25A430, 36A430 and 36E430 have

roller bearings on the connecting rod journal end; these are not

replaceable.

b. Installing a New Crankshaft or Fly wheel: Before installing

a new crankshaft or flywheel, the crankshaft taper must be ground into the

tapered bore of the flywheel. Apply grinding compound to the crankshaft

taper. Slide the crankshaft into the flywheel bore. Rotate the crankshaft in

the flywheel bore until a good finish is obtained. Thoroughly wash away all

grinding compound with diesel fuel or gasoline. (Figure A-76).

c. Camshafts: These must be replaced when wear or damage

appears on the cam faces.

d.

Roller Bearings:

Replace whenever wear or damage is

evident.

Figure A-76. Installation of New Crankshaft or Flywheel

A-31