TM 5-4220-211-12&P

raises atmospheric air to a pressure of about 3200 PSIG. The compressed air is purified by the purification chamber and

is then used to fill the SCUBA diver tank block. The gas detector kit is used in conjunction with the carbon dioxide and

carbon monoxide test tubes to detect the presence of these contaminants in the compressed and purified air.

1-3

RELATED PUBLICATIONS. For further information concerning components used in this equipment but which

are beyond the scope of this manual, the following publications are recommended:

a. Engine Service and Repair Instructions. Briggs and Stratton Corp. Manual Part No. 271461, covering Engine

Model 18A430.

b. Detector Tube Handbook. Available from National Draeger Inc., Park View Drive, Pittsburgh, Pa. 15205.

Special List 2340E, 4th edition.

Section II

GENERAL DESCRIPTION

1-4.

AIR COMPRESSOR UNIT. The air compressor is a portable, three stage, three cylinder, reciprocating, air cooled

machine which is capable of supplying purified breathing air to fill air bottles. The compressor is driven by an air cooled,

single cylinder, manually started diesel engine. A conventional V-belt drive is used to connect the diesel engine to the

compressor block. The maximum brake horsepower of the engine is 6.2 BHP at 3600 RPM. A welded construction

tubular steel frame provides appropriate mounting points for the instruments, purification chamber and all major

components. A resilient mounting system is used to minimize transmission of engine vibration into other components.

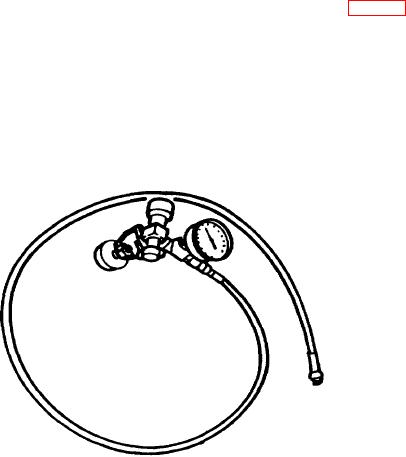

The compressor and purification chambers are interconnected. A fill hose and manifold (Fig. 1-2) with fill adapter (Fig. 3-

5) must be used to connect the discharge of the air purifier chamber to the diver tank block.

1-5.

DIVER TANK BLOCK. The diver tank block consists of two aluminum tanks joined together by a manifold, and

fitted on a double tank harness for diver convenience and maneuverability. The two-cylinder air manifold is basically an

on-off valve that controls the air supply of the two cylinders. The manifold is rated 3000 psi and is equipped with an air

reserve valve that will shut off automatically at approximately 500 psi. The reserve supply can then be activated by means

of a reserve valve knob, or rod connected to the knob. Charging of the cylinders is by means of a filler hose connected

from the compressor to the center yoke of the manifold.

Figure 1-2. Fill Hose and Manifold

1-2