TM 5-4220-211-12&P

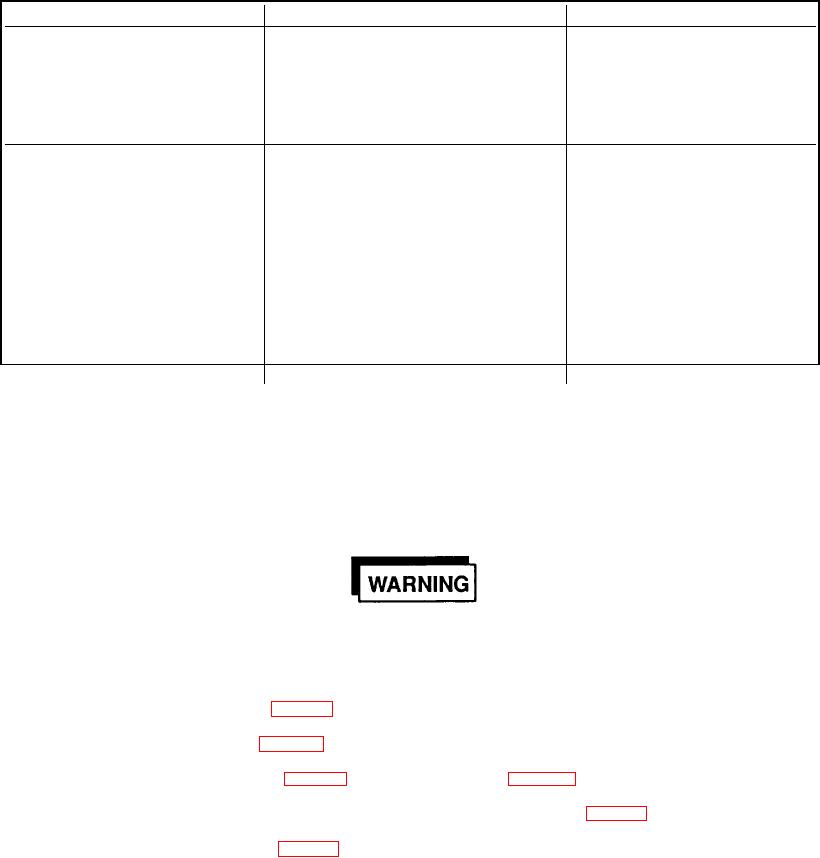

Table 4-4. ENGINE TROUBLESHOOTING (con't)

Symptom

Probable Cause

Correction

Excessive Oil Consumption

Piston Rings Worn or Sticking,

Inspect and Free Rings or

Cylinder

Overhaul Engine

Wall(s) Scuffed or Scratched

Oil Leaking

Inspect and Tighten Fittings as

Needed

Unusual Engine Knocks

Loose Mounting Bolts

Inspect and Tighten

and Noises

Any Loose Bolts

Engine Overload

Reduce Engine Load

Loose Flywheel

Tighten Flywheel Mounting Bolts

Damaged Gear Teeth

Replace Any Gear with Broken

Teeth; Also Examine Gear it

Engages for Damage

Incorrect Timing

Correct Injection Pump Timing

NOTE

This table is not intended to cover every possible symptom, but is rather a list of the more

frequent problems and some of their causes.

Section V

REMOVAL OF MAJOR ASSEMBLIES

4-8.

COMPRESSOR. The compressor may be removed from the frame as follows:

Compressor piping may contain high pressure. Never attempt to service or repair any

portion of the compressor until all pressure has been released to the atmosphere.

a.

Remove drive belt. (Ref. para 4-4g).

b.

Disconnect gauge lines (40, Fig. 4-2).

c.

Remove gauge panel (22, Fig. D-2).

d.

Disconnect discharge hose (30, Fig. D-2) at the final separator (Fig. D-12).

e.

Remove 4 bolts, 4 nuts, 4 lock washers and 12 flatwashers (45, 46, 47, 48, Fig. D-2).

f.

Move compressor assembly (1, Fig. D-2) straight out through beltguard side of the frame and place on a flat,

level surface.

4-15