10-10

U.S. Navy Diving Manual—Volume 2

a.

Partial Pressure Mixing with Air. Oil-free air can be used as a Nitrogen

source for the partial pressure mixing of NITROX using the following

procedures:

Prior to charging air into a NITROX bottle, the NITROX mixing

technician shall smell, taste, and feel the oil-free air coming from

the compressor for signs of oil, mist, or particulates, or for any

unusual smell. If any signs of compressor malfunction are found,

the system must not be used until a satisfactory air sample has been

completed.

Prior to charging with oxygen, to produce a NITROX mix, the

NITROX-charging technician shall charge the bottle to at least 100

psi with oil-free air. This will reduce the risk of adiabatic compres-

sion temperature increase. Once 100 psi of oil-free air has been

added to the charging vessel, the required amount of oxygen should

then be added. The remaining necessary amount of oil-free air can

then be safely charged into the bottle. The charging rate for

NITROX mixing shall not exceed 200 psi per minute.

WARNING

Mixing contaminated or non-oil free air with 100% oxygen can result in a

catastrophic fire and explosion.

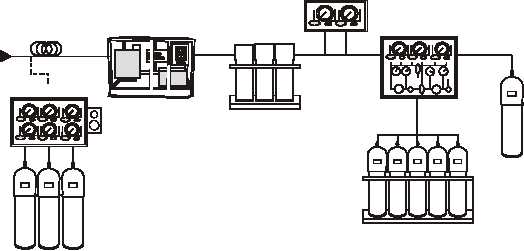

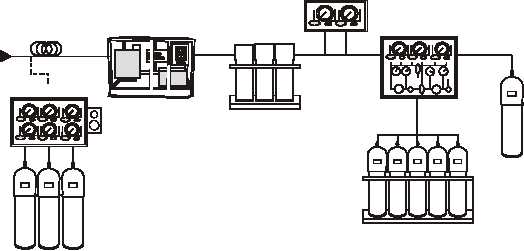

Figure 10-3. NITROX O2 Injection System.

NITROX Storage Bank

NITROX

SCUBA

Cylinder

Distribution Panel

Oxygen Analyzer

Oil-Free H.P. Compressor

Gas Mixing Coils

Ambient

Air Intake

Oxygen Injection System

- Oxygen

- Regulator

Oxygen Supply

Purification System

X