TM 5-4220-211-12&P

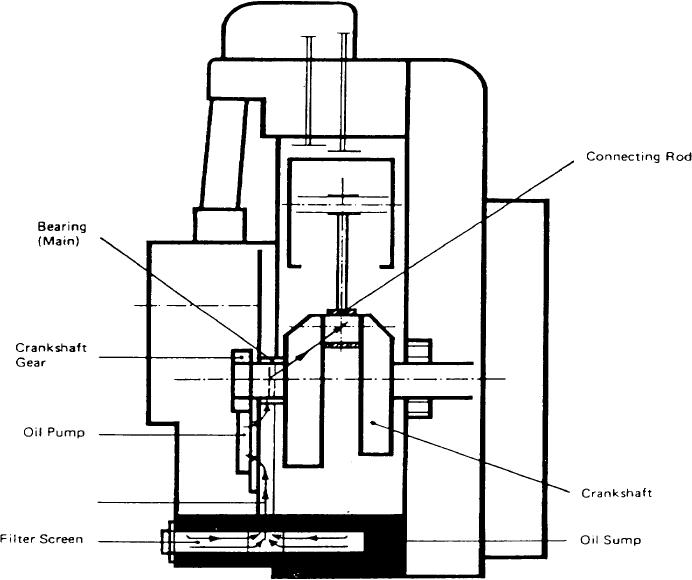

LUBRICATION/COOLING SYSTEM

Figure A-74. 15A430/18A430 Lubrication System

A-12. OIL PRESSURE TESTING.

Remove the oil pressure gauge plug (found on side of crankcase on

15A430/18A430: at oil cooler on 2 cylinder engines) and install an oil pressure gauge. On models 15A430 and 18A430,

the oil pressure at idle should be at least 12 psi (.8 BAR) while the pressure at full engine speed should not exceed 60 psi

(4.0 BAR). V-Twin engine oil pressure should fall between 45 psi (3.0 BAR) and 150 psi (10.0 BAR). Models 25A430,

36A430 and 36E435 are splash lubricated - no oil pressure check is necessary.

A-13. LUBRICATION SYSTEM MAINTENANCE. All Farymann engines require heavy-duty lubricating oils of at least

CC and preferably CD (quality (API Service Classification). The following chart indicates the temperature range of popular

oil viscosities. See General Information -- Maintenance for oil change intervals.

Figure A-75.

A-14. COOLING SYSTEM OPERATION. A flywheel fan provides flow of air ducted to cool all parts of the cylinder and

cylinder head, which are heavily finned for heat dissipation.

Although uncomplicated and effective, this cooling system will not perform properly if:

a. The engine is operated in an enclosed space without provision for the intake of cool air.

A-30