TM 3-240-212-14&P

APPENDIX C

MAINTENANCE ALLOCATION CHART

Section I. INTRODUCTION

categories for the M20 breathing apparatus This chart is

C-1.

General

to be used by all levels of maintenance to Insure

The maintenance allocation chart lists the authorized

complete support of the equipment

maintenance functions for the four maintenance

Section II. EXPLANATION OF COLUMNS

modules with the next higher assembly.

C-2.

Maintenance Functions

b. Column 2-- Component/Assembly Column 2

Maintenance functions authorized are limited to and

contains the noun names of components, assemblies,

defined as follows

subassemblies, and modules for which maintenance Is

a. Inspect. To determine the serviceability of an

authorized

item by comparing its physical, mechanical and/or

c. Column 3-- Maintenance Functions Column 3 lists

electrical characteristics with established standards

the functions to be performed on the item listed in column

through examination.

2

b. Test. To verify serviceability and detect incipient

d. Column 4-- Maintenance Category Column 4

failure by measuring the mechanical or electrical

specifies, by the listing of a "work time" figure In the

characteristics of an item and comparing those

appropriate subcolumn/s), the lowest level of

characteristics with prescribed standards.

maintenance authorized to perform the function listed in

c. Service. Operations required periodically to keep

column 3 This figure represents the active time required

an item In proper operating condition, i.e., to clean

to perform that maintenance function at the indicated

(decontaminate), to preserve, to drain, to paint, or to

category of maintenance If the number or complexity of

replenish fuel, lubricants, hydraulic fluids, or compressed

the tasks within the listed maintenance function vary at

air supplies.

different maintenance categories, appropriate "work timer'

d. Replace. The act of substituting a serviceable

figures will be shown for each category The number of

like type part, subassembly, or module /component or

man-hours specified by the "work tine" figure represents

assembly) for an unserviceable counterpart

the average time required to restore an Item (assembly,

e. Repair The application of maintenance services

subassembly, component, module, end item or system) to

or other maintenance actions to restore serviceability to

a serviceable condition under typical field operating

an item by correcting specific damage, fault, malfunction,

conditions This time includes preparation time,

or failure in a part, subassembly, module (component or

troubleshooting time, and quality assurance/quality control

assembly), end item, or system

time in addition to the time required to perform the

specific tasks identified for the maintenance functions

C-3. Explanation of Columns

authorized in the maintenance allocation chart

a. Column 1-- Group Number. Column 1 lists group

numbers, the purpose of which is to identify components,

assemblies, subassemblies, and

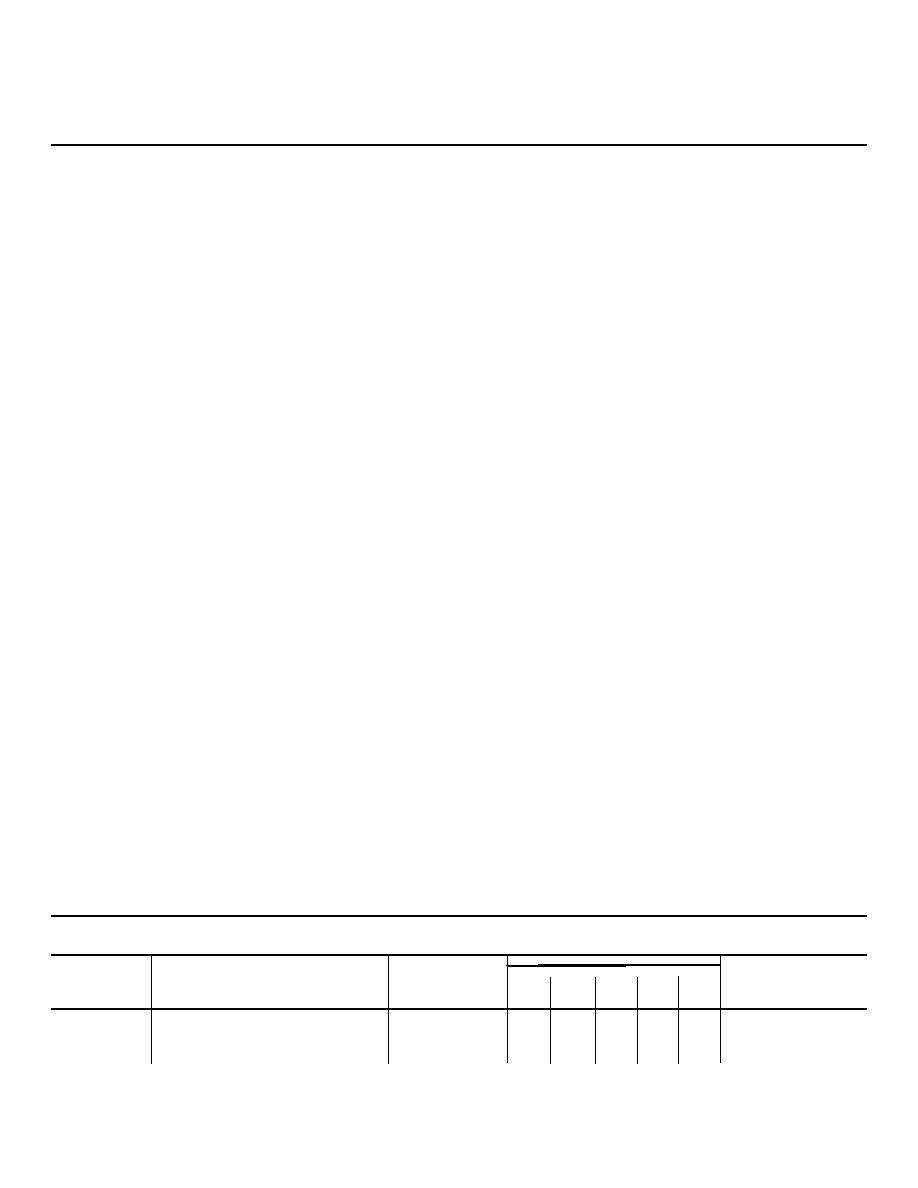

MAINTENANCE ALLOCATION CHART

for

M20 OXYGEN GENERATING BREATHING APPARATUS

(1)

(2)

(3)

(4)

(5)

MAINTENANCE CATEGORY*

COMPONENT

GROUP

MAINTENANCE

TOOLS

ASSEMBLY

NUMBER

FUNCTION

AND

C

O

F

H

D

EQUIP

0100

FACEPIECE

Inspect

0.1

Test

0.5

C-1